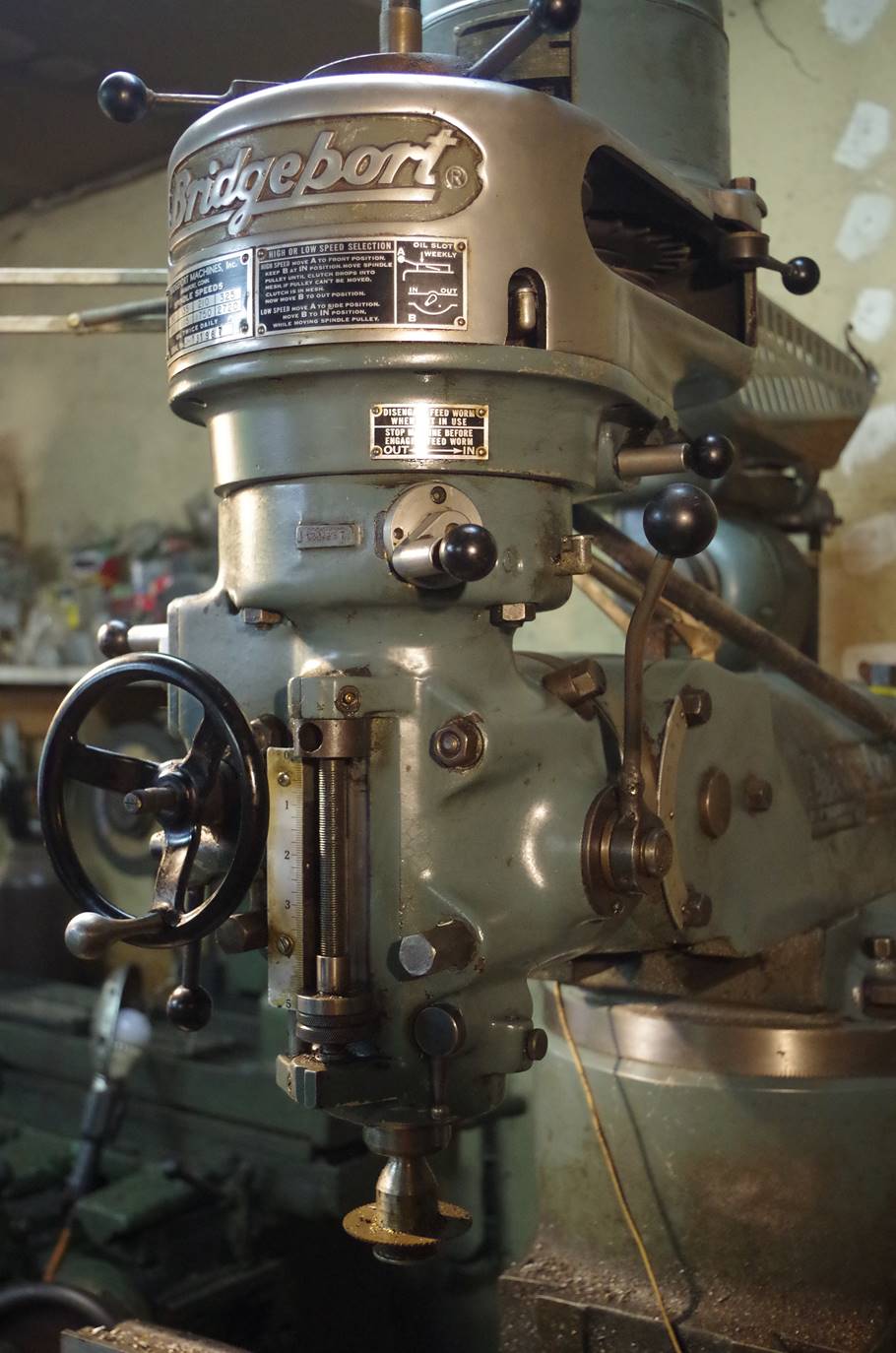

Bridgeport Mill

Figure 1: Bridgeport series I

The Bridgeport milling machine has been the standard in manual vertical knee mills for about the last 50 years. The Bridgeport is certainly a versatile and well made milling machine. Imitation is the sincerest form of flattery and a proliferation of Bridgeport clones and mills described as “Bridgeport types” can be found. Bridgeport Machines started manufacturing milling machines in 1938 in Bridgeport, Connecticut with the older style round-ram type machine. In 1956, the company introduced the modern dovetail ram type machine, which remained essentially unchanged throughout the life of the company. In 2004, the original Bridgeport Machines company went bankrupt. The rights to the name are now owned by Hardinge who continue to manufacture Bridgeport mills.

Figure 2: Bridgeport Series 1

My Bridgeport is a series I machine and was manufactured in 1969. It is equipped with Mitutoyo magnetic scales on its X and Y axes connected to a Mitutoyo 2-channel DRO, a vertical slotter attachment (Figure 3), and a Bridgeport power feed on its X axis (Figure 4). The head is a 1 HP “J-head” (Figure 5) with four-step matched cone pulleys. Gear reduction in the head enable a low-range, so it is an eight speed machine. The motor is the original Bridgeport three phase 1 HP motor, but I rewound the motor to run on a 120V single phase line because I do not have three phase electrical service. I probably have the only Brideport that runs on 120V single phase power and still has the original Brideport motor, albeit electrically modified.

Figure 3: Vertical slotter attachment mounted on the rear. The slotter is powered by its own 1/3 HP motor. A six-step matched cone pulley set provides a speed selection of 70, 100, 145, 205, 295, and 420 strokes per minute. The stroke is adjustable from 0 to 4”.

Figure 4: Bridgeport X-axis power feed

Figure 5: Eight speed Bridgeport Head

Figure 6: Vertical Slotter at work planing a bevel gear.

Figure 7: Genuine Bridgeport milling vise

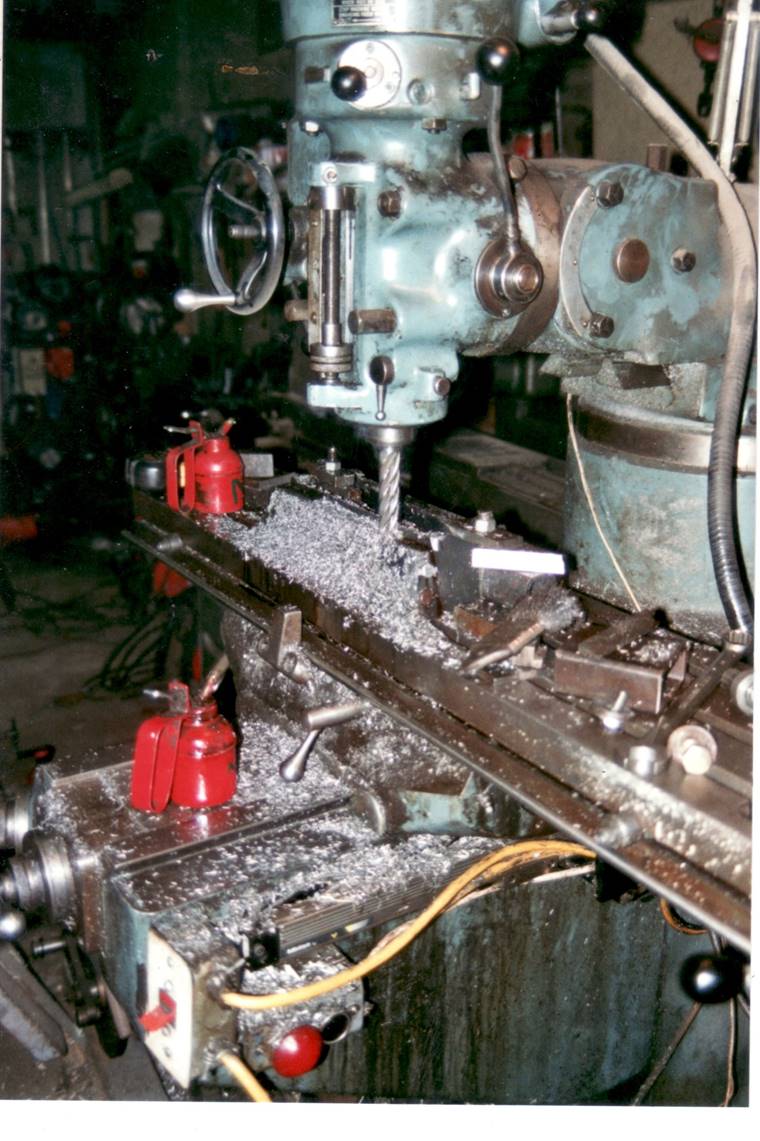

Figure 8: Making chips.

Figure 9: Internal slotting. The ring is a V-belt adapter to be fitted over the flat belt pulley of my 13” South Bend lathe.